introduction

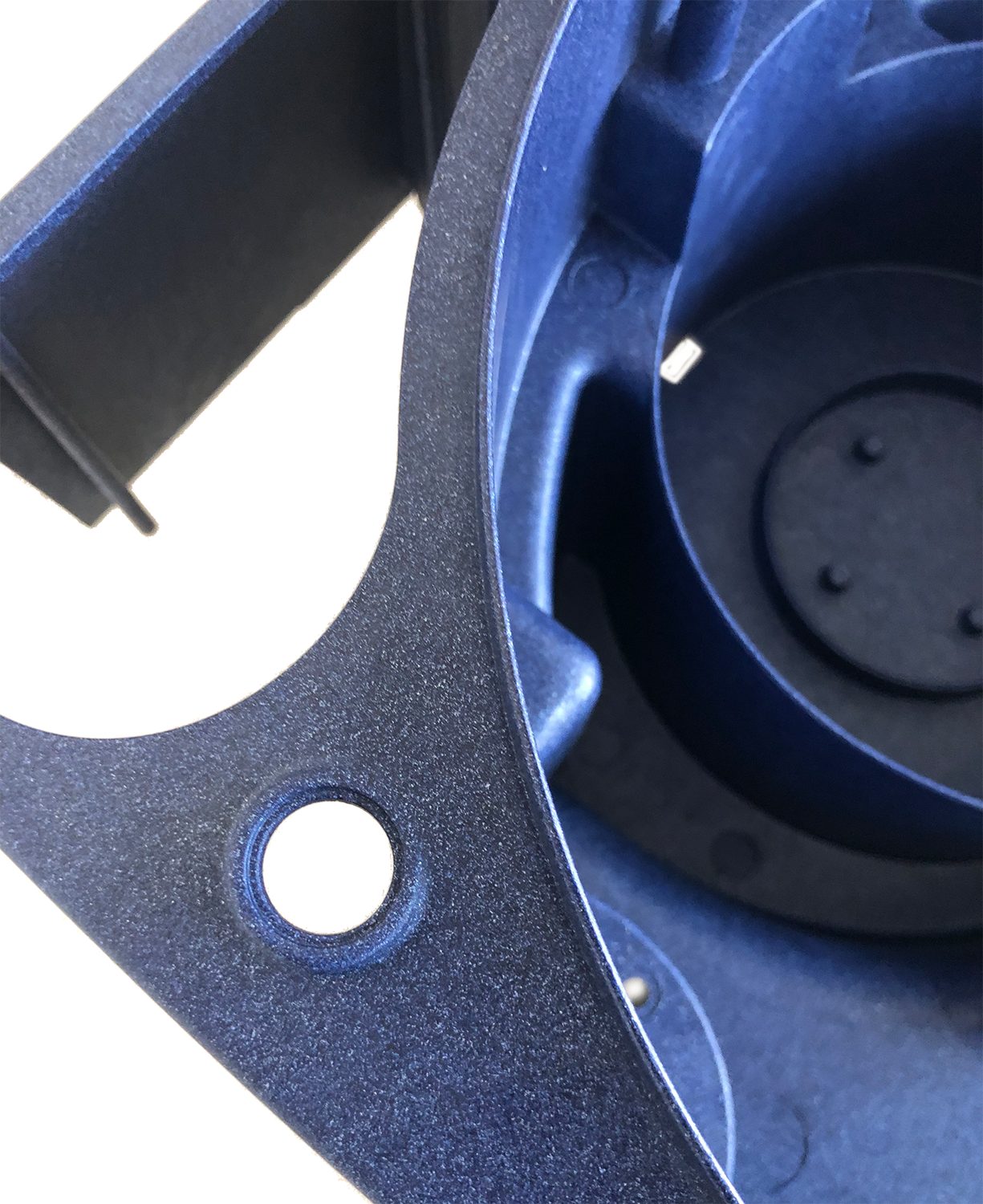

Recon Polymers has developed an efficient process to convert PolyAl into widely applicable plastics.

PolyAl is the residue of polymers and aluminum foil remaining after paper mills have recovered the paper fibers from used beverage cartons.

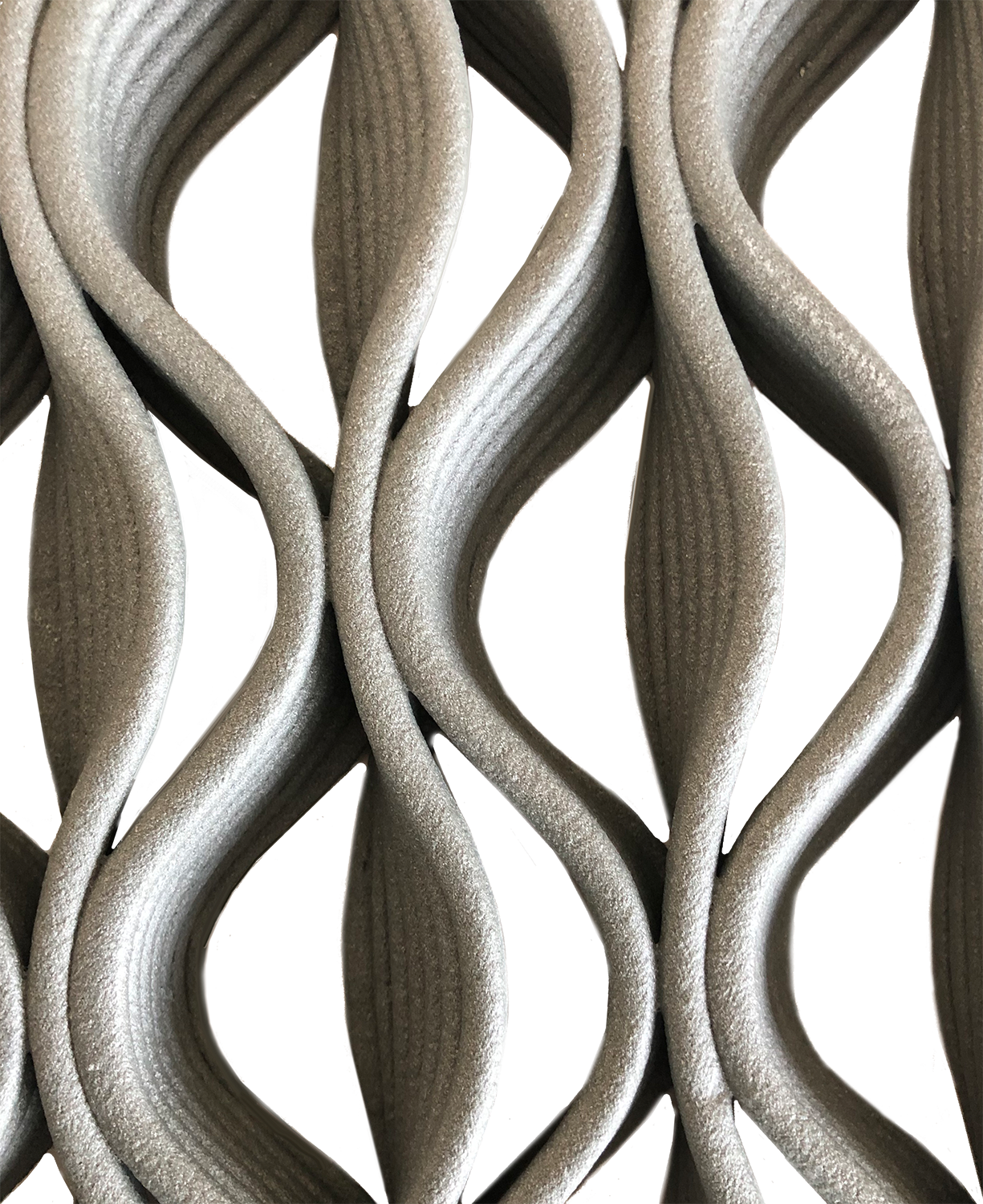

Recon Polymers is, after many years of development able to efficiently transform PolyAl into plastics directly suitable for further processing.

vision

Recon Polymers demonstrates that PolyAl as a raw material has a positive economic value for the entire chain. This enables mainstream circularity, from raw material to end market applications.

context

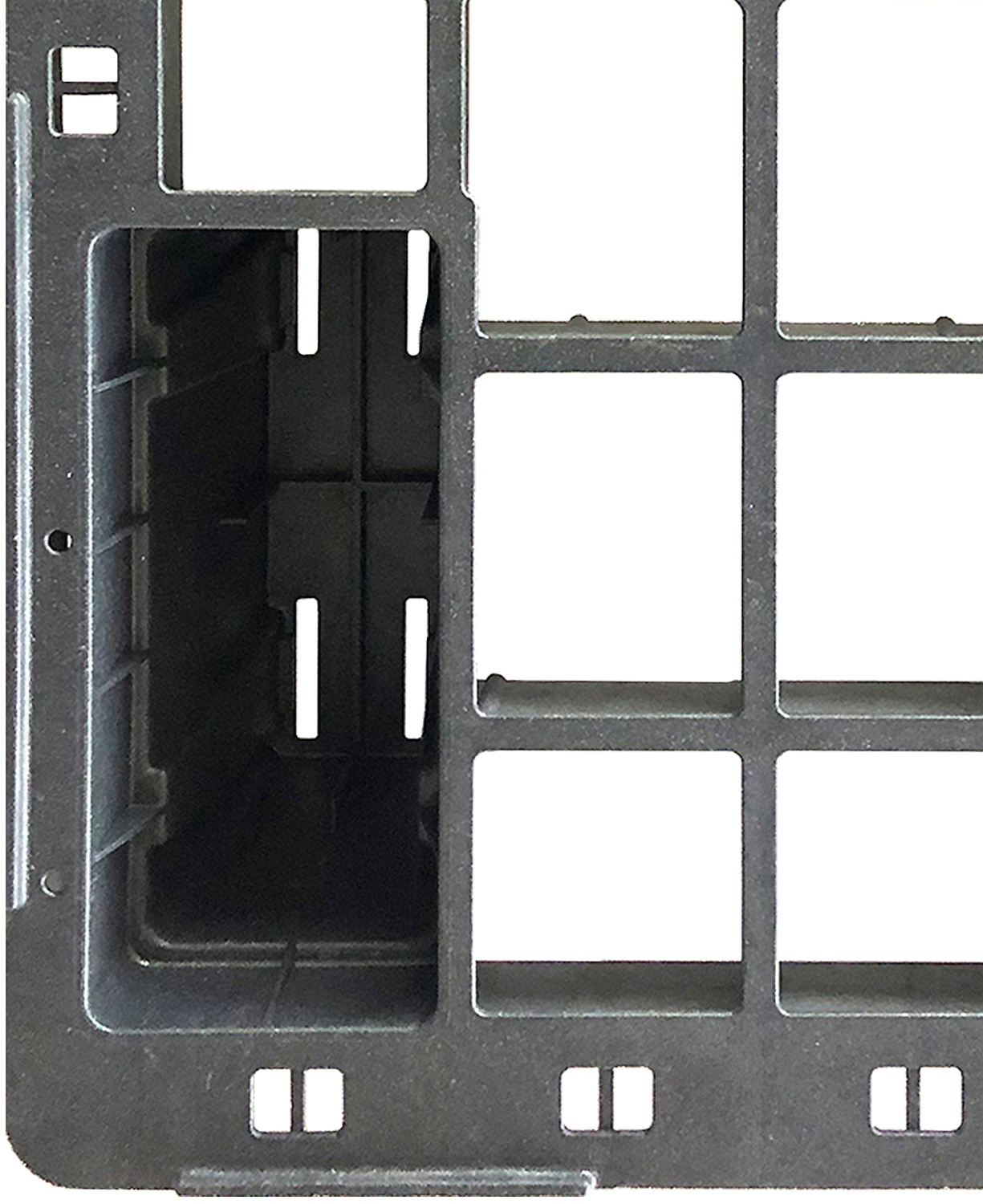

A beverage carton consists of ±75% paper fiber and a ±25% mix of different polymers [HDPE, LDPE, PP] combined with aluminium foil. This mix of materials guarantees a long shelf life for the contents of a beverage carton.

Complete recycling of used beverage cartons is realized in two steps. Paper mills recover the paper fiber and in an additional process the polymers and aluminum are transformed in widely applicable plastics.

Beverage cartons are used and disposed of by consumers. After collection and sorting, the combined material is transported to paper mills where the paper fibers are recovered to produce, amongst others hygiene paper and kraftliner.

After the paper fiber recovery step PolyAl remains. This stream is suitable for further recycling through the Recon Polymers process.

process

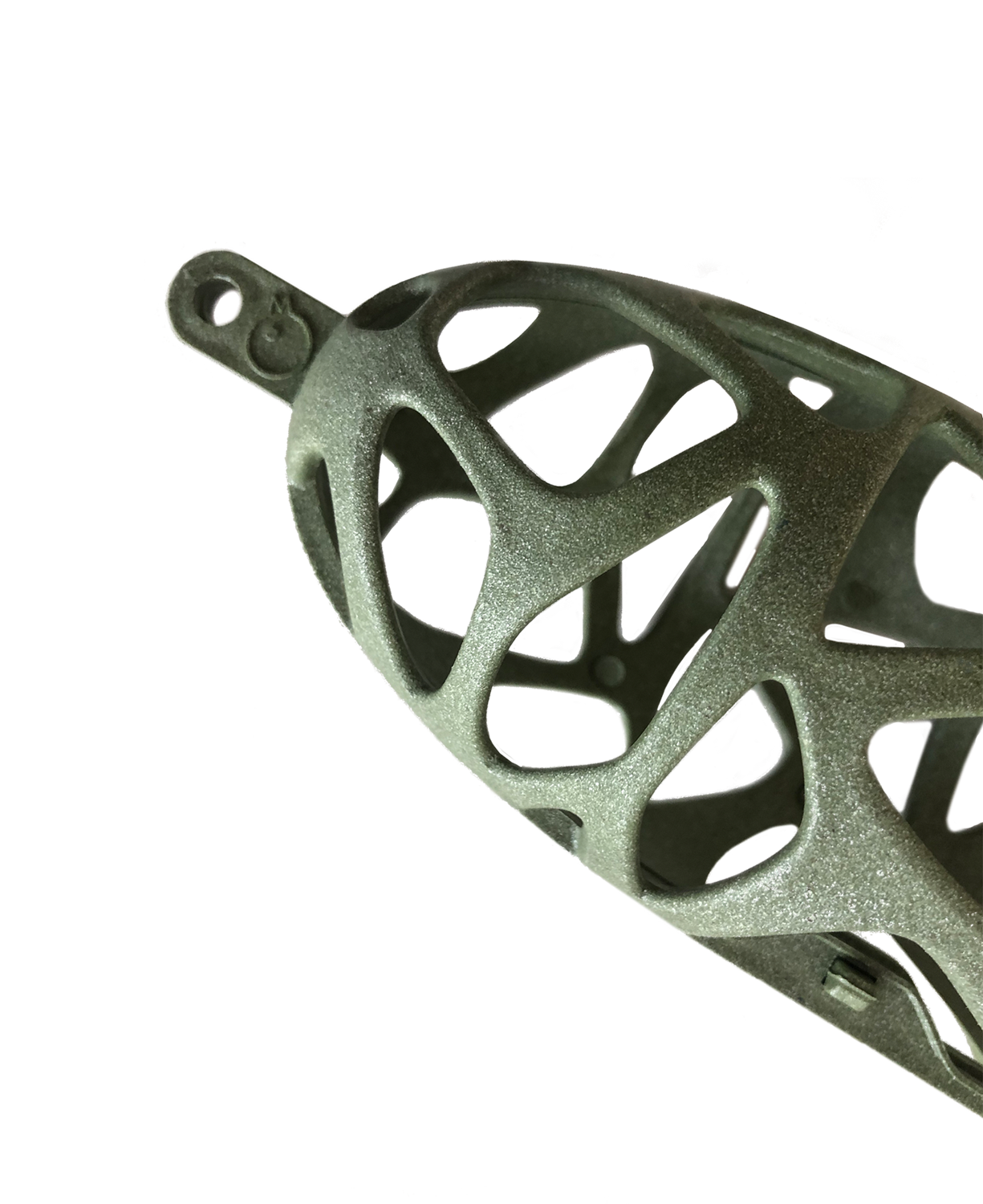

The Recon Polymers process is characterized by a recycling yield of over 99% based on a net mass balance. This against a low energy consumption and with a high separation rate of ±98% of the LDPE/ aluminium foil fraction and the hard fraction, consisting of mainly HDPE caps and closures.

During the process the only ‘reject’ is vaporized water. This is moisture added during the paper mill pulping process that is still part of PolyAl-reject.

The Recon Polymers plant is based on mechanical principles without adding water, chemicals or heat and has a capacity of at least 6,500 tons output per year. Based on an average moisture content of 22%, an input quantity of approximately 8,000 tons PolyAl can be processed per year.